SPORTSWEAR

Why Are My Jersey Letters Peeling and How Can I Prevent It?

Table of Contents

- What Causes Jersey Letters to Peel?

- Jersey Lettering 101: The Main Application Methods

- Which Application Method is the Highest Quality?

- How to Fix Peeling Letters With an Iron

- How Factory Choices Affect Letter Durability

- Conclusion

Introduction

It’s a frustrating moment for any sports fan or player. You pull your favorite jersey out of the wash, only to see the edges of a letter or number starting to lift. As someone who manufactures jerseys for a living, I get questions about this all the time. Peeling letters are a common problem, but they are often preventable. This article will explain why your jersey letters are peeling, what you can do to fix them, and most importantly, what to look for in a quality jersey to prevent it from happening in the first place. My goal is to give you the knowledge to care for the jerseys you own and make smarter choices for your next purchase.

1. What Causes Jersey Letters to Peel?

Your favorite jersey is starting to look worn out because the letters are peeling. You worry that with each wash, it will only get worse, eventually ruining the entire look. The first step to preventing this is understanding what causes it.

Jersey letters peel primarily due to three reasons: low-quality adhesive on the vinyl, improper application at the factory (incorrect heat, pressure, or time), and incorrect washing and drying methods.

Each of these factors can compromise the bond between the lettering and the fabric. Sometimes it’s a single issue, and other times it’s a combination of all three. Let’s dive deeper into each cause so you can identify the likely culprit for your jersey and learn how to avoid it in the future.

1.1 Low-Quality Heat Transfer Vinyl (HTV)

The foundation of a durable heat-pressed number is the material itself. Heat Transfer Vinyl (HTV) comes in many different grades and qualities. Cheaper vinyls use lower-grade adhesives that are more susceptible to breaking down from heat, friction, and detergents. Some manufacturers cut costs by using these inferior materials to offer a lower price point. Unfortunately, this cost-cutting measure comes at the expense of durability. A quality HTV is designed to stretch with the fabric and withstand dozens of wash cycles without losing its bond. When I work with buyers like Marco from Italy, we always discuss material quality first. I explain that investing a little more in premium vinyl from reputable suppliers is one of the best ways to ensure the final product is something his customers will be happy with for a long time. A peeling letter is often the first sign that corners were cut on material quality.

1.2 Improper Application at the Factory

Even the best quality vinyl will fail if it’s not applied correctly. The application of heat-pressed letters is a science that relies on a perfect balance of three elements: temperature, pressure, and time. If the heat press is too hot, it can damage the fabric or the vinyl itself. If it’s not hot enough, the adhesive won’t activate properly to create a strong bond. The same goes for pressure—too little, and the vinyl won’t adhere evenly; too much, and it can push the adhesive out from the edges. Finally, the pressing time must be exact. I remember early in my career, we had a small batch of jerseys where the letters started peeling after the first wash. We traced the problem back to a heat press that wasn’t properly calibrated, shortening the press time by just a few seconds. That small error was enough to ruin the batch. This is why professional factories use industrial-grade, calibrated equipment and have strict quality control to ensure every jersey is pressed perfectly.

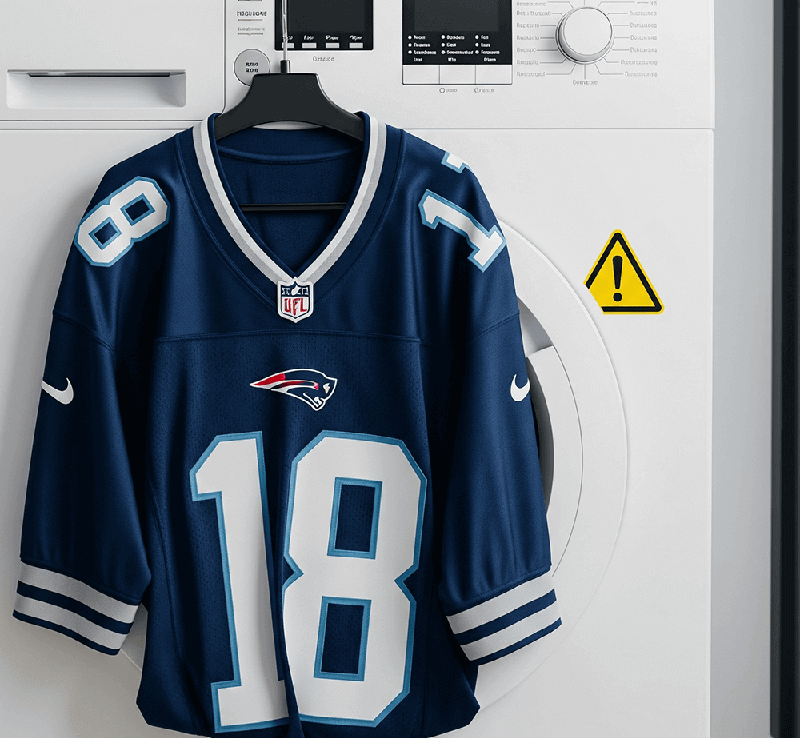

1.3 Incorrect Washing and Care

Sometimes, the jersey is made perfectly, but the peeling is caused by how it’s cared for at home. Jerseys, especially those with heat-pressed lettering, require special care. Throwing them in a hot wash cycle with regular laundry is a recipe for disaster. High heat is the enemy of adhesive. It can soften the glue, causing the letters to loosen and peel. Fabric softeners can also be a problem, as they contain chemicals that can degrade the adhesive over time. The friction from a rough wash cycle or the high heat of a machine dryer can also cause the edges of letters to lift. To maximize the life of your jersey, you should always:

- Turn the jersey inside out before washing.

- Wash in cold water on a gentle cycle.

- Avoid using fabric softeners.

- Never put it in the dryer. Always hang it to air dry.

2. Jersey Lettering 101: The Main Application Methods

Not all jersey lettering is created equal, and the differences are huge. If you choose the wrong type for your needs, you might be setting yourself up for disappointment and peeling problems down the road. Let’s break down the common types so you can see what makes each one unique.

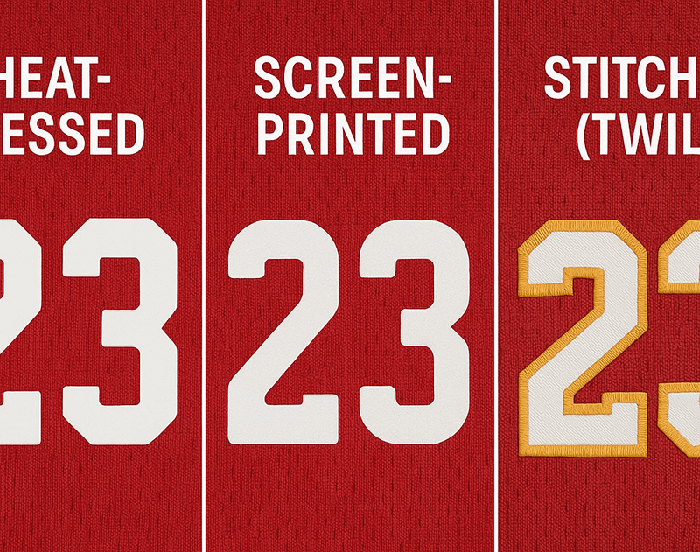

The three main jersey lettering methods are Heat-Pressed (Vinyl), where letters are glued on; Screen-Printed, where ink is applied; and Stitched (Twill), where fabric letters are sewn onto the jersey.

Each method has its own pros, cons, and ideal use case, affecting everything from the jersey’s appearance and feel to its overall durability. Knowing these differences will help you understand why some jerseys last a lifetime while others don’t, and will help you choose the right style for your specific needs.

2.1 Heat-Pressed (Vinyl)

This is the most common method for custom jerseys, especially for individual names and numbers. Heat Transfer Vinyl (HTV) is a sheet of polyurethane material with a heat-activated adhesive on one side. The letters and numbers are cut from the vinyl with a plotter, positioned on the jersey, and then applied using an industrial heat press. Its main advantages are speed, affordability, and the ability to easily customize single jerseys, making it perfect for amateur teams and smaller orders. However, as we’ve discussed, its main weakness is its susceptibility to peeling if the materials are low-quality or the application is poor. It’s a fantastic option when done right by a reputable manufacturer, but it’s also the source of most peeling complaints.

2.2 Screen-Printed

Screen printing involves pushing ink through a mesh screen (a stencil) directly onto the fabric. Each color in a design requires its own screen. This method is excellent for team logos or sponsor graphics that are the same across a large batch of jerseys. The ink soaks into the fabric slightly, creating a durable and soft feel once cured. It’s generally more durable than heat press vinyl and is less likely to peel, though it can crack or fade over many years of heavy use and washing. The downside is that it’s not practical for customization like individual player names and numbers because a new screen would be needed for each one, which would be very expensive and time-consuming. It’s best for large-volume orders of identical designs.

2.3 Stitched (Twill)

This is the premium, professional-grade option. Twill is a durable, polyester-blend fabric. Letters and numbers are cut from sheets of twill, positioned on the jersey, and then sewn down around the edges with a zigzag stitch. Often, a design will use multiple layers of twill to create colored outlines. This method is the most durable by far because the letters are physically attached to the jersey with thread. It’s what you’ll find on authentic jerseys for professional leagues like the NHL, MLB, and NBA. The look is high-end, and it has a classic, textured feel. The main drawbacks are that it’s significantly more expensive and time-consuming to produce, and the added weight of the fabric and stitching can be noticeable compared to other methods.

3. Which Application Method is the Highest Quality?

You want the absolute best for your jerseys, something that will last for years. Making the wrong choice means you might face the frustration of peeling letters all over again. Here is a clear answer on which method stands the test of time and professional use.

For ultimate durability and a premium, professional look, Stitched (Twill) lettering is considered the highest quality method. It is physically sewn onto the jersey, making it virtually impossible to peel off.

While other methods have their place, nothing beats the longevity and authentic feel of stitched lettering. Its physical bond to the garment is simply superior to any adhesive. Let’s explore another modern alternative that also eliminates peeling entirely.

3.1 Why Stitched Twill is the Gold Standard

The reason stitched twill is regarded as the highest quality comes down to one simple fact: it uses a mechanical bond (thread) instead of a chemical bond (adhesive). The zigzag stitch around the edge of each letter and number physically anchors the twill to the jersey fabric. This means it can’t peel or lift in the same way an adhesive-based letter can. It can withstand the rigors of professional sports, including intense physical contact, stretching, and industrial laundering. This is why it’s the exclusive choice for authentic, on-field jerseys in most major sports leagues. While it’s the most expensive option, the investment translates directly into longevity. However, there is another "peel-proof" method popular in soccer: sublimation. In sublimation, the ink is dyed directly into the fabric fibers, so there is no layer to peel at all. For lightweight performance jerseys where a stitched patch would be too heavy, sublimation is the highest-quality choice for integrating names and numbers seamlessly.

4. How to Fix Peeling Letters With an Iron

You’ve just noticed a letter peeling on your favorite jersey. Don’t throw it away just yet! You’re worried about making it worse, but there is a simple technique you can try at home to save it.

You can often re-adhere peeling letters using a household iron. To do this safely, place a thin piece of parchment paper or a cotton cloth over the letter and press down with an iron on a medium, no-steam setting for 15-20 seconds.

This quick fix can help re-activate the adhesive and get your jersey back in wearable condition. However, it’s crucial to do it correctly to avoid melting the vinyl or burning the jersey. Let’s walk through the steps carefully.

4.1 Step-by-Step Guide for a DIY Fix

This repair can work well, but think of it as a first-aid fix rather than a permanent solution. The bond will likely not be as strong as the original factory press.

- Prepare the Jersey: Lay the jersey flat on a hard, heat-resistant surface like an ironing board. Make sure the peeling letter is smooth and in its correct position.

- Get a Protective Layer: Do NOT apply the iron directly to the vinyl letter. You will melt it. Place a piece of parchment paper (baking paper) or a thin, dry cotton cloth (like a pillowcase) over the entire letter or number.

- Set Your Iron: Set your iron to a medium heat setting. Crucially, make sure the steam function is turned OFF. Steam can introduce moisture that will ruin the adhesive.

- Press Firmly: Press the iron down firmly on top of the protective layer over the peeling area. Do not slide the iron around. Hold it in place with steady pressure for about 15-20 seconds.

- Let It Cool: Remove the iron and let the area cool down completely. Once cool, carefully check if the letter has re-adhered. If edges are still loose, you can repeat the process for another 10-15 seconds.

4.2 What NOT to Do

Avoiding common mistakes is just as important as following the steps.

- Don’t Use High Heat: Too much heat will melt the vinyl and possibly scorch the jersey fabric. Start with medium heat and only increase slightly if needed.

- Don’t Use Steam: Steam will prevent the adhesive from bonding properly and can trap moisture. Always use a dry iron.

- Don’t Rush the Cooling: The adhesive bonds as it cools. Peeking or moving the letter while it’s still hot can ruin the bond. Be patient.

5. How Factory Choices Affect Letter Durability

Why does one team’s jersey last for years while another’s peels after a few months? It often feels like a lottery, but it’s not. The jersey’s lifespan is largely decided by choices made at the factory. Let me pull back the curtain on how manufacturing decisions directly impact durability.

A factory’s investment in high-quality vinyl, modern calibrated equipment, and strict quality control processes is the single biggest factor in preventing peeling. Premium materials and precise application create a bond that cheaper methods simply cannot match.

For a buyer, understanding these behind-the-scenes factors is key to sourcing reliable products. When a supplier focuses on quality from the start, you get a product that lasts, which protects your reputation and keeps your customers happy.

The Manufacturer’s Responsibility

As a manufacturer, preventing peeling letters starts long before the jersey is ever pressed. It begins with sourcing. We vet our suppliers for Heat Transfer Vinyl, testing different grades for elasticity, adhesive strength, and wash durability. Choosing a premium HTV costs more upfront, but it saves everyone from problems down the line. Next is the equipment. An industrial heat press provides consistent, even pressure and accurate temperature across its entire surface, which a smaller, cheaper machine cannot guarantee. We regularly calibrate our machines to ensure every single jersey receives the exact heat and pressure for the exact amount of time required for a perfect bond. Finally, there’s quality control. Our team inspects jerseys after pressing to check for a complete and even application. This is the level of detail I discuss with my clients. They need to know that their supplier isn’t just applying letters, but is engineering a durable product. When you see a jersey with peeling letters, it’s often a sign that the manufacturer skipped one of these crucial steps to save a little money.

Conclusion

Peeling jersey letters are a preventable problem. The cause is usually a combination of low-quality materials, incorrect factory application, or improper washing. While you can sometimes perform a temporary fix with an iron, the best strategy is prevention. Understanding the difference between heat-pressed, screen-printed, and stitched lettering allows you to choose the right method for your needs, with stitched twill being the highest quality for durability.

Ultimately, the best way to avoid peeling is to source your jerseys from a reputable manufacturer that invests in high-quality materials and professional processes. If you’re in the market for custom jerseys that are built to last, with lettering that stays put, my team at Sihola Sports would be happy to help.